Delivering a New Control Panel for an Extension and ECS Upgrade

For a waste recycling company

Client

Bottom Ash Waste Recycling Plant

Service Provided

Systems Integration

Location

West Yorkshire

Project Overview

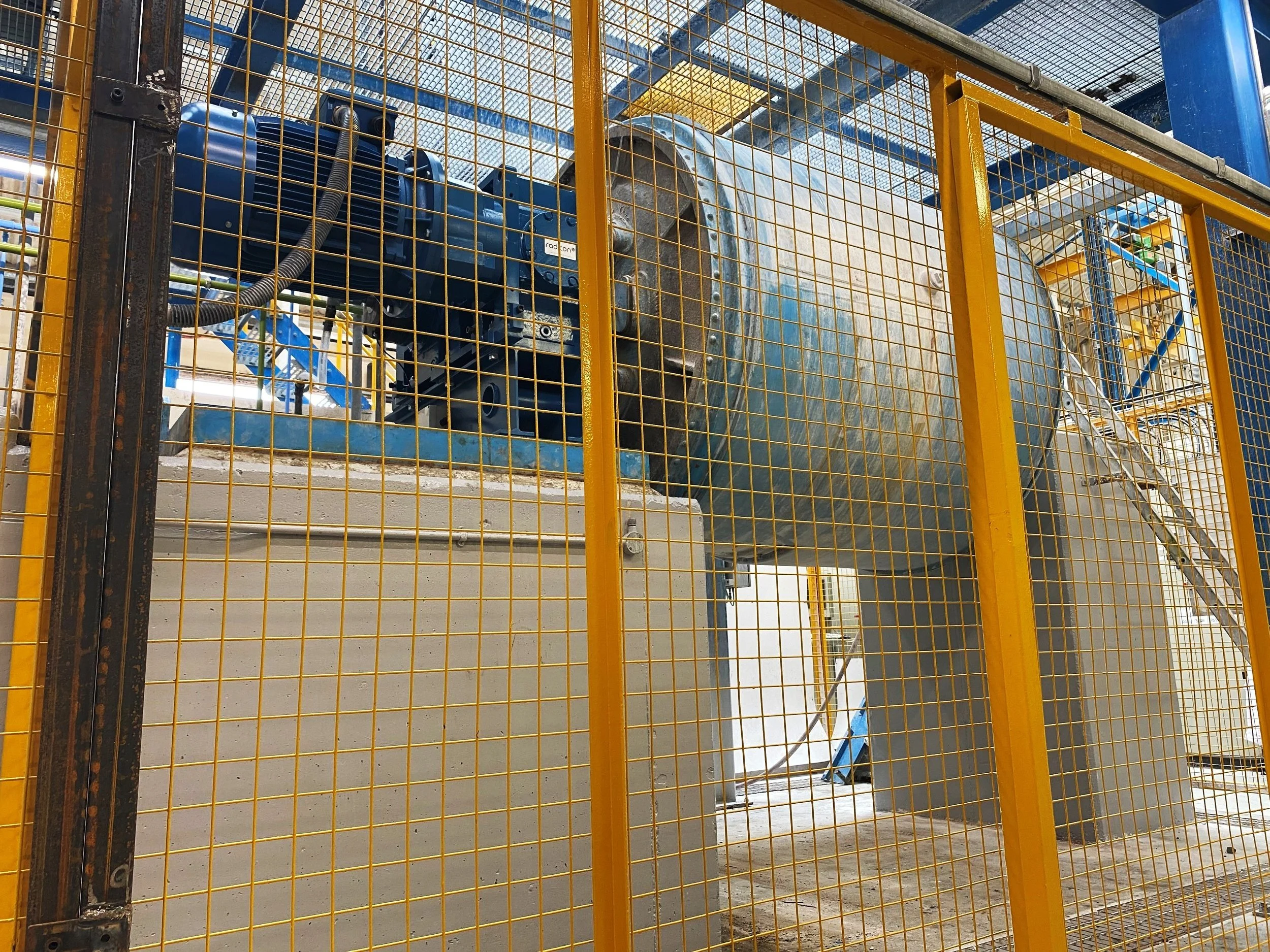

As part of a wider upgrade programme, our customer required a new control panel system to support an extension with additional ECS’s (Eddy Current Separator) they were installing in their system. This was a significant undertaking, involving both the design and installation of a four-cabinet control panel (total length 4.8m) and the associated cabling and switch room works to accommodate higher power ratings and new sequencing requirements.

Our role was to deliver a robust, integrated solution that worked seamlessly alongside existing infrastructure, while also providing the flexibility and resilience needed for future expansion for the bottom ash incinerator of a waste recycling company.

Bottom Ash Waste Recycling Plant

Robust, integrated solution supporting an added ECS extension

Process Installation that incorporates Electrical and Contol Installation

The Challenge

The project presented two main challenges:

Integration with the existing plant and process – controls, cabling, and interconnections all had to be designed with the new equipment requirements in mind, considering vibration and environment

Seamless connection between new and existing systems – the new panel needed to operate as a self-contained package but also communicate reliably with the existing control infrastructure.

Alongside this, the system had to be compact, efficient, and safe, while meeting the increased demand of higher power loads.

The Solution

Control Panel Installation

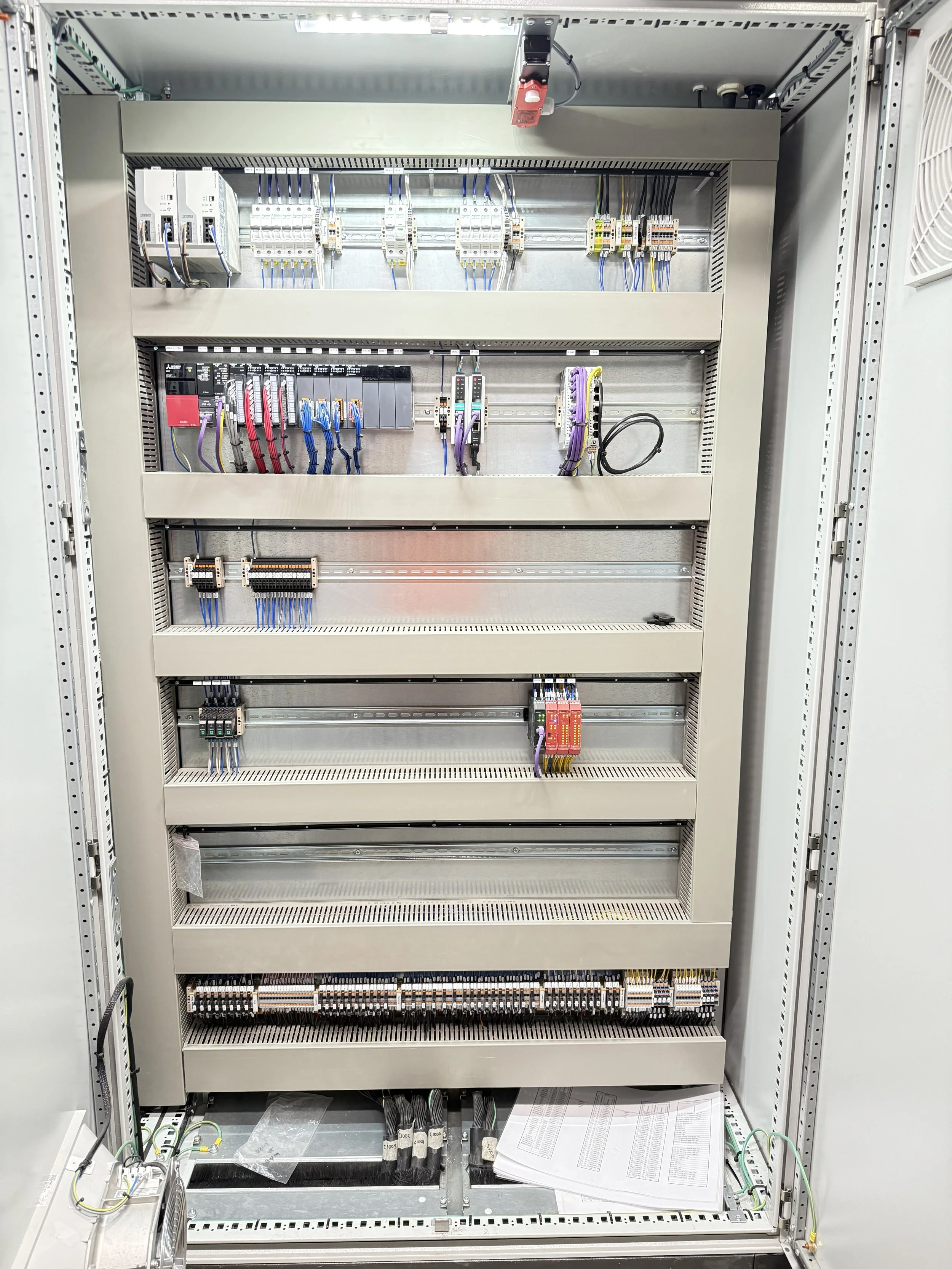

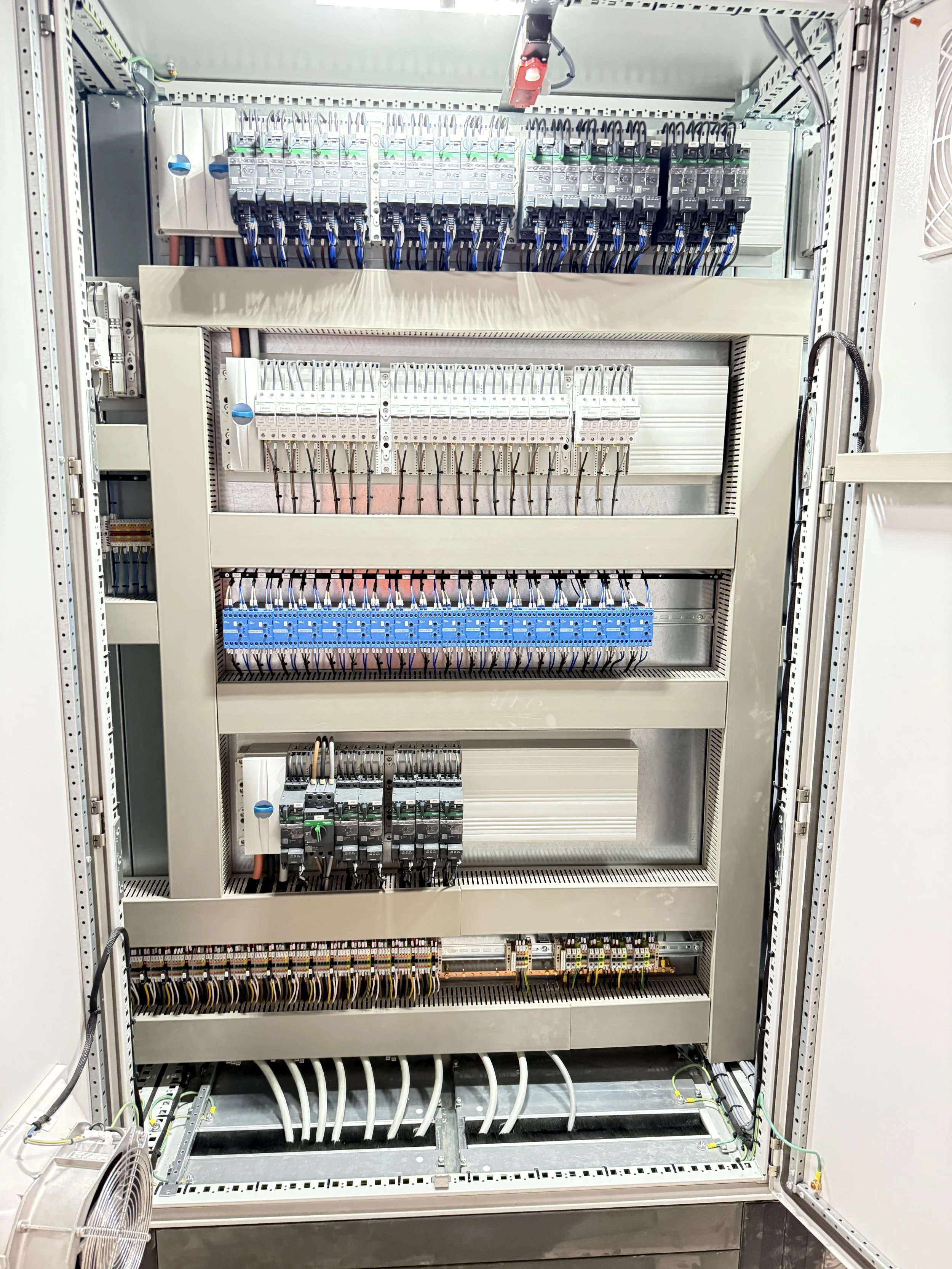

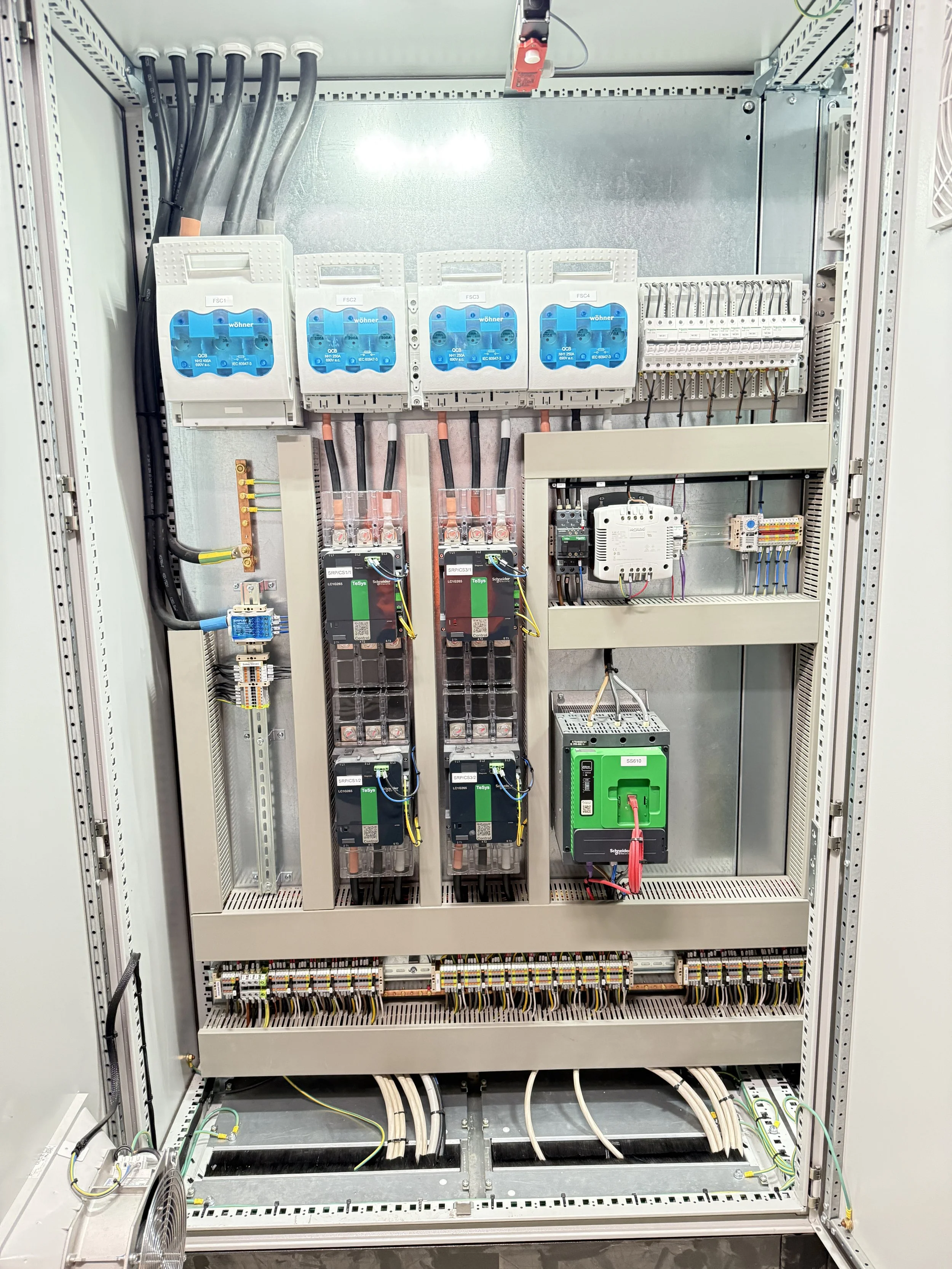

We supplied and installed four mild steel cabinets (each 1200mm wide, totalling 4800mm in length), fitted with the required drives and controls as outlined in the project’s electrical overview. The design incorporated:

New busbar systems for VSDs, DOLs, and braked drives

A new PLC to manage communication between old and new panels, with updated sequencing to accommodate the additional equipment

An electronic door interlock system fed from the existing control panel

Four brake resistors dedicated to the ECSs

A new remote isolator panel with a 1000A isolator and an upgraded 24Vdc maintained supply

Comprehensive updates to the electrical drawings

Switch room Installation

Within the switch room, we carried out both panel installation and equipment upgrades:

Installing the new control panel and uprated components within the existing panel to handle higher power ratings

Running new cabling between the old and new panels

Installing brake resistors on the ladder rack

Installing the new isolator control panel

Upgrading the power supply cabling between DB1, the isolator panel, and CP1 with 240mm cabling to safely handle increased loads

Installing a new cable ladder above the control panel to manage the additional wiring infrastructure

Cabling and Building Infrastructure

To connect and support the new equipment, we designed and installed a cable management system across both existing and new building areas. This included:

New cable trays running from the switch room, around the existing building, and into the new extension

Additional trays around the perimeter of the new building section to carry motor and control cabling

New junction boxes to consolidate auxiliary control wiring (rotation sensors, pull wires, PTCs, controls) and to manage intermediary motor connections

Supply and installation of cabling for motors and controls, along with new motor isolators where required

The Results

Smarter Controls and Safety

The control system was designed not only to meet technical requirements but also to improve efficiency and safety. By using compact Schneider DOL starters with simplified 24Vdc comms, we reduced wiring complexity while maintaining reliable communication. Safety features such as electronic door interlocks, fault feedback loops, and clear terminal layouts provide operators with complete peace of mind.

Following the successful implementation of this turnkey solution, the manufacturer reported increased energy efficiencies with the ensuing costs savings, and improved operational flexibility over the previous DOL solution. All of which helped this traditional industry enjoy a much-needed modern makeover.

Download Case Study Here

View Installation Slides Here

Our Case Studies