First IBA Processing Facility in Australia

Bespoke Control and Automation Solution for the Waste-to-Energy Sector

Client

Blue Phoenix Group

Location

Australia

Service Provided Systems Integration

Project Overview

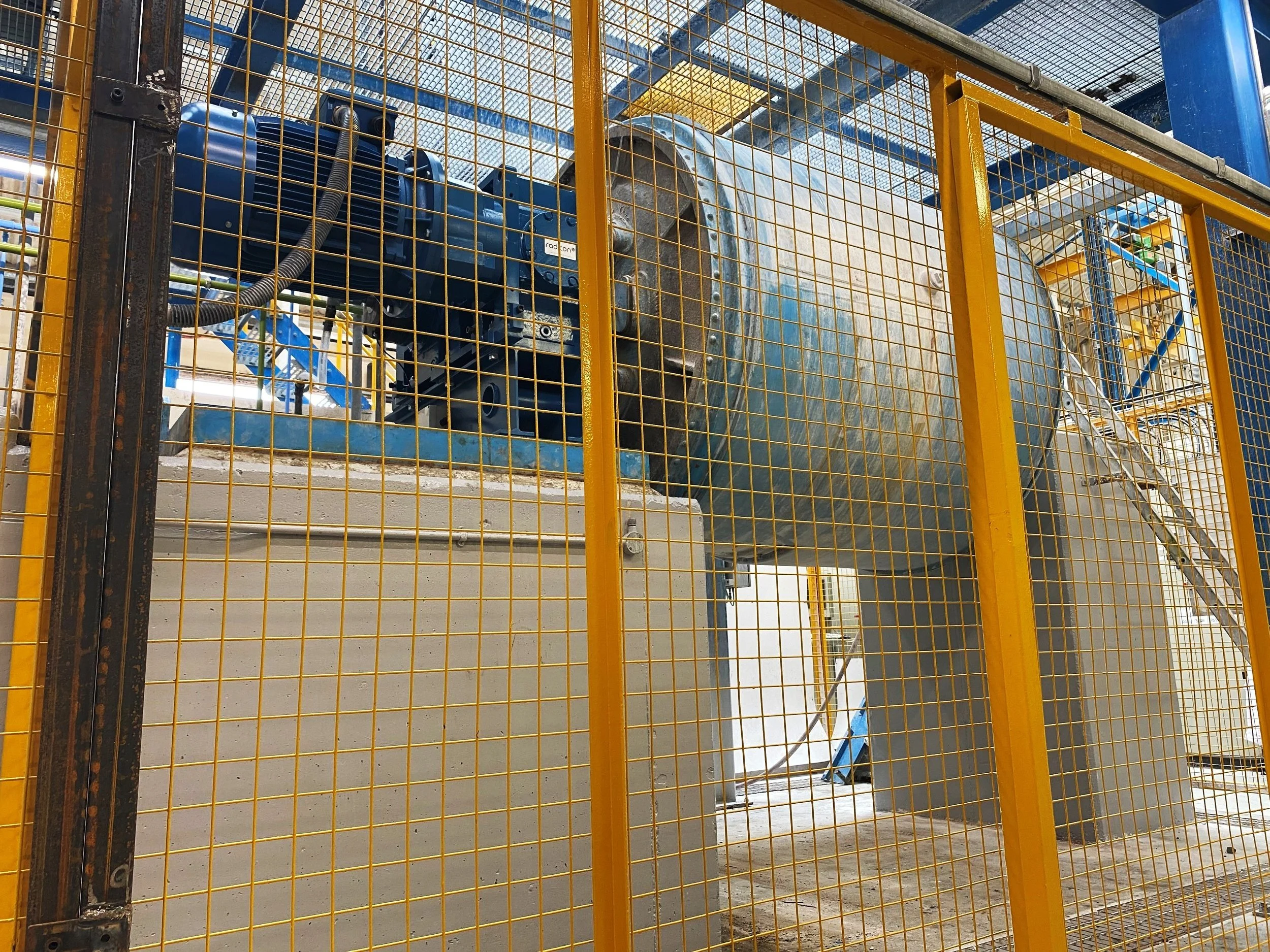

Total Automated Solutions were contracted to build a bespoke Motor Control Centre (MCC) for the first IBA (Incinerator Bottom Ash) Processing Facility.

As part of the wider Waste-to-Energy development in Western Australia, the project required a robust, future-ready control and automation solution to support bottom ash processing, ECS separation, and associated material handling systems. Total Automated Solutions played a pivotal role in the design, construction, commissioning, and integration of the MCC and associated control systems.

The objective of our client is to divert waste from landfills and improve the circularity of the Waste-to-Energy sector in a collaboration with Avertas Energy.

The Challenge

The project demanded a highly engineered, safety-critical control solution capable of managing complex waste processing operations while meeting Australian standards and tight programme constraints. Key challenges included:

Coordinating multiple motor control strategies (VSDs, DOLs, braked DOLs, and soft starters)

Managing high-power distribution via large busbar systems and heavy-duty isolators

Implementing advanced safety architectures including emergency stops, pullwires, electronic interlocks, trapped key systems, and delayed safe torque-off

Delivering reliable, scalable communications while reducing wiring complexity

Supporting remote commissioning across a 12-month period with UK–Australia time differencestem; we knew this was a project we could not refuse.

Waste Management - Waste Recycling

Design, construction, commissioning, and integration of the MCC and associated control systems

Used multiple motor control strategies (VSDs, DOLs, braked DOLs, and soft starters

“Total Automated Solutions delivered at a Quality Standard above their peers in Australia. The professional approach to our project delivered by Kevin is testament to why Blue Phoenix Group chose to partner with Total Automated Solutions. ”

The Solution

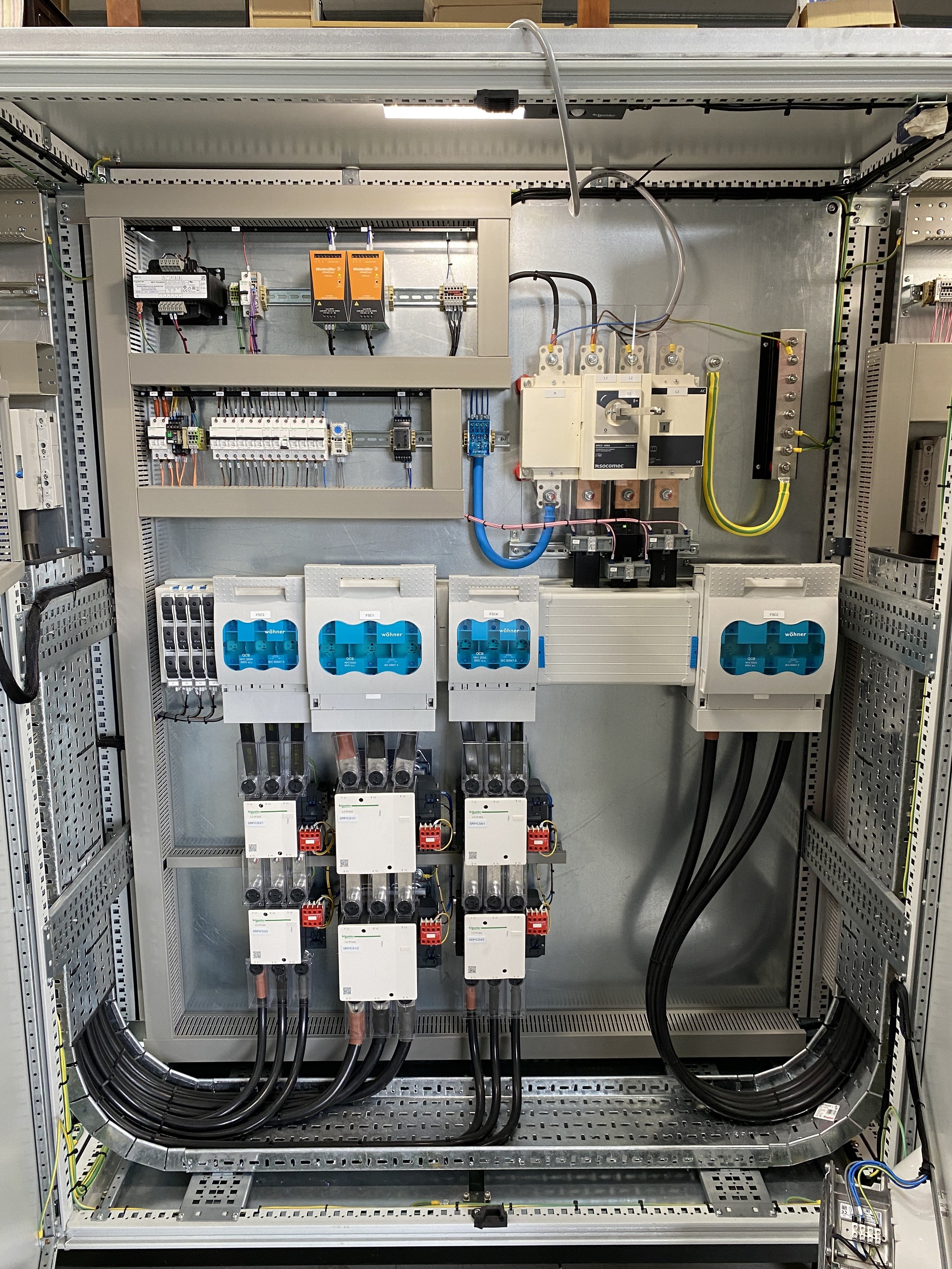

Control Panel Architecture

Large-scale multi-cabinet with top cable entry and terminals mounted along the cabinet tops with structured terminal layouts to suit existing cabling. Installation in a container prior to shipping, which meant only final installation and commissioning was needed on site.

Cabinet configuration:

Cabinet 1: Common controls, main PLC rack, Estop and pullwire safety systems

Cabinets 2 & 3: DOL and braked drives with secondary PLC rack

Cabinet 4: Main incomer with 1000 A T-type busbar system

Cabinets 5–7: VSDs and soft starters with third PLC rack

External wall-mounted isolator enclosures housing-maintained PLC power supplies

Visual voltage indication on panel doors using Switchtec LED indicators

Custom plinths and reinforced cabinet tops using angle bar for rigidity and safe lifting

Panel designs split for safe transport and efficient on-site installation

Communications & Control

Multi-PLC architecture distributing I/O across cabinets

Ethernet-based communications using Modbus TCP and RTU via Moxa gateways

Dual-port VSD networking and structured daisy-chain topology

Direct digital feedback to PLCs for enhanced diagnostics and reduced fault-finding time

Dual power metering to support operational transparency and remote monitoring

The Conclusion

This project demonstrates Total Automated Solutions’ expertise in delivering large bespoke control, high-integrity control and automation systems for the waste management and waste-recycling sector. By combining disciplined engineering, proven reference designs, and maintainable solutions tailored to demanding industrial environments, and Schneider Electric technologies, Total Automated Solutions continues to support complex recycling and resource recovery facilities worldwide.

Electric Motor Control & Drives

Schneider LUB “all-in-one” DOL starters with advanced bases and integrated communications

Class 10 and Class 20 overload protection selected to suit motor inertia

Schneider soft starters for high-inertia applications such as crushers

Schneider VSDs across ECS rotors and conveyors with:

Screened motor cabling

Integrated PTC protection

Delayed safe torque-off for ECS systems

Integrated braking systems with fault and status feedback

Commissioning & Delivery

Total Automated Solutions’ Director, Kevin Chapman, led commissioning activities, providing exceptional on-site and remote support throughout the project lifecycle.

He provided support remotely in the lead up to commissioning via Teams and email over 12 months, without delay or complaint even when his help was needs late at night in the UK due to the time difference to Australia.

The Results

Successful delivery of Australia’s first IBA processing facility with

Safe, reliable, and maintainable Schneider Electric-based control systems

Improved operational visibility, diagnostics, and future scalability

On-time commissioning with zero failures

A long-term automation platform supporting circular economy objectives

Client Testimonials

“Total Automated Solutions and their Director Mr Kevin Chapman have played a pivotal role in the successful construction of our plant in Western Australia, from the design and construction of our MCC, with exacting quality standard and pragmatic design ensuring that the MCC did exactly what was expected of it upon commissioning.”

— Blue Phoenix Group formally recognised Total Automated Solutions’ contribution:

“Kevin’s depth of knowledge and experience working closely with Peter Rumping (BPG EPC Manager) has enabled BPG to install and commission our plant on time and without any failures. His disciplined and pragmatic approach to the design and commissioning of our plant was the difference between success and failure. Without this level of skill and quality, and the willingness to go above and beyond, our project would have been delayed.” BPG Managing Director Western Australia, Ian Lynass.

“Total Automated Solutions delivered at a Quality Standard above their peers in Australia. The professional approach to our project delivered by Kevin is testament to why Blue Phoenix Group chose to partner with Total Automated Solutions.” He continued.

Our Case Studies