Reviving Efficiency

Restoring Operational Functionality to Screening Handling Equipment at a Wastewater Treament Plant

Client

SPIRAC - Solid Handling Solutions

Location

London, UK

Service Provided Repair & Electrical Installation

The Challenge

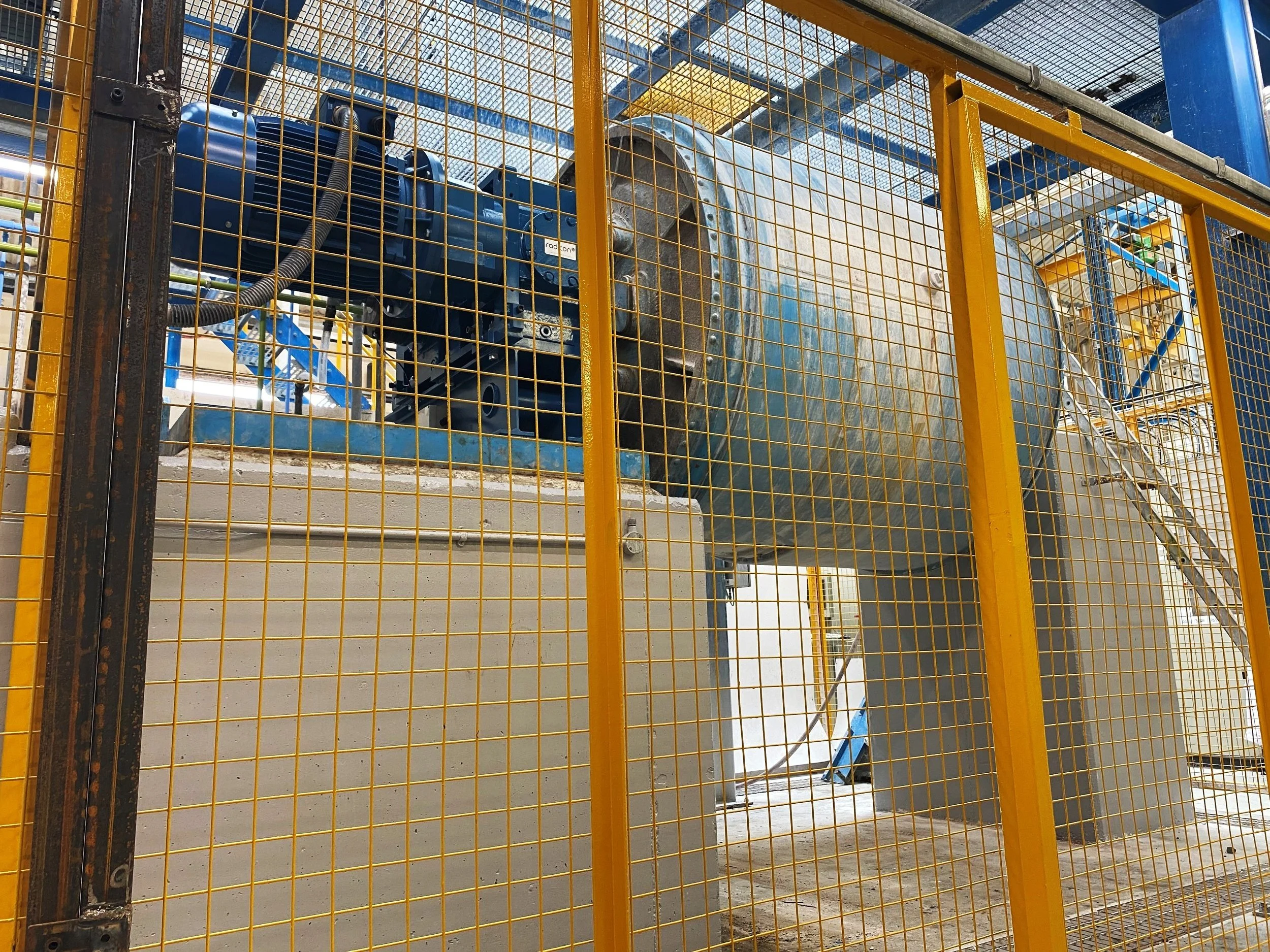

Total Automated Solutions undertook a crucial project involving SPIRAC equipment, focusing on the restoration of efficiency in a wastewater treatment facility. The primary function of the SPIRAC equipment is to wash and compact screenings removed from the inlet screens. However, a challenge arose when the end user of the SPIRAC equipment had removed some downstream plant which resulted in damage to the existing installation. The removal had been done in a temporary fashion, with no consideration given to how it would impact the operation of the screenings handling equipment.

Wastewater

Identify exact damage to installation

Team was able to repair, replace and restore

“In spite of the tough conditions on site, the Total Automated Solutions team worked with the SPIRAC team - as seamlessly as always. There was a bit of a rats nest of redundant cabling to resolve, and repair to some containment. The location wasn’t the most hygienic of locations to say the least, but ‘Hard Hats’ off to the lads who just cracked on without a moan or a groan.”

Rob Iwanuschak

The Solution

Total Automated Solutions to the rescue - we stepped in to address the issues and restore optimal functionality. The following steps were taken:

✔ Testing, isolation, and removal of redundant cabling.

✔ Repair and restoration of damaged cable containment.

✔ Inspection and repair of control panels, replacing components like lamps, contactors, isolators, and ammeters with like for like new counterparts.

✔ Thorough understanding of the core issues and why the equipment would not run in automatic mode.

The Results

Through commissioning the machine, all the instruments and linking out any removed infrastructure that was not present, we managed to get the Megawashers and Spiropress units back running in automatic, thus saving the end user time and money in maintenance and consumed electricity. Want similar results? Contact us.

Our Case Studies