Landfill Site with a Future

Delivering a full-turnkey service: design, build and install two replacement control kiosks at a local waste reclycling site.

Client

Former Landfill Site

Service Provided

Systems Integration

Location

North Yorkshire

The Challenge

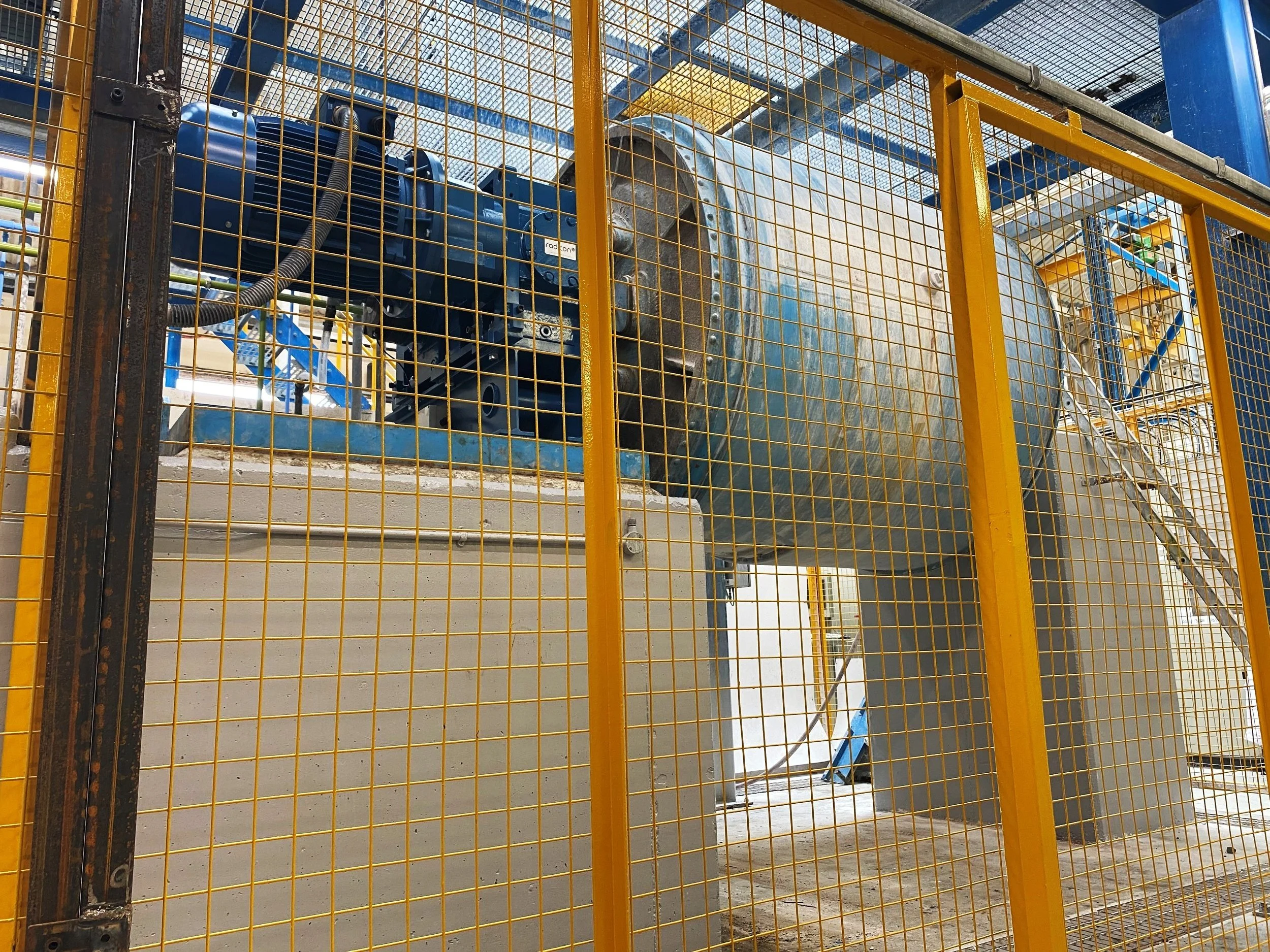

A former non-hazardous landfill isn’t just changing - it’s evolving with purpose. The focus for transformation is on three core areas. Firstly, it continues to serve as a Waste Transfer Station, linking local collections to a Waste Recovery Park. Secondly, legacy landfill gas is being harnessed with battery energy storage, and finally, plans for a 16.5 MW solar farm promise to turn restored land into a source of clean power. This is a story of circular economy in action. Waste is redirected, energy is reclaimed, and biodiversity is nurtured. Every step forward is a step away from landfill dependency and toward a resilient, low-carbon future. With the added benefit of treating walkways, cycle-paths and bridal paths between meadows and planted trees. As part of this evolution the facility needed to upgrade its core control infrastructure.

A solution was sort that was not only reliable, built to last, and compliant with modern safely and operational standards, but could be installed with minimum impact on their daily operations.

Former Lanfill & Waste Recycling Plant

Upgrading the facilities core control infrastructure

ProDesign, build, install and commission new control system

Due to our long-term proven track record and collaborative partnership, our client chose Total Automated Solution to handle this critical systems upgrade project and the end result was a fast, reliable and accurate control system without interruption to our operations.

Rob Iwanuschak - Managing Director, Total Automated Solutions

The Solution

To replace the existing control systems we installed two GRP kiosks with wall-mounted control panels. They were fitted out with Integrated pump starters, PLCs (with easy swap-out capability), flow meter brackets (the flow meters in the existing panels were relatively new, and could be easily moved into the new panels), minicass relays, 110VAC transformer, 24VDC PSU. Both panels were built and factory-tested in our workshop prior to delivery.

Installation & Commissioning Process

Any risks and mitigation was considered through planning. The environmental safeguards were managed via design refinements and capped landfill protocols. During the removal of the existing control panels, the site team prepared for the new panels with cable and core markings - this ensured that connection to the new panels were quick and efficient. Once the old panels were removed, the new kiosks were immediately placed and secured on plinths. Our Total Automated Solutions engineers prioritised swiftly reconnecting the mains and motor supplies, transferring flow meters and instrument cables. Once this had been achieved, the panels underwent a full system testing and commissioning. This concluded with the NICEIC inspection certificate issued and all paperwork and permit signed-off.

The Results

While the site’s transformation is underpinned by several of our customer’s strategic pillars - our contribution ensures the infrastructure is robust, compliant, and future-proofed. The site’s infrastructure is not just ready - it’s resilient, compliant, and built to last.

The new control systems have brought significant improvements, boosting operational reliability and efficiency across the site. The future-ready infrastructure provides a robust foundation for the waste site’s continued growth, reinforcing its critical role in the local low-carbon, circular economy strategy.

This project was a success not only because our team of site engineers worked seamlessly to deliver on time and to specification, but also because we did so with zero disruption to our customers ongoing operation.

Download Case Study Here

Our Case Studies