Minimising Loss, Maximising Safety

Improved Efficiency and Safety for Food Industry Processes

Services Provided Automation and Control

Client Food Manufacturer

Location Yorkshire, UK

The Challenge

The food production company faced a challenge in loosing efficiently packaging powdered goods caused by multiple breakdowns and slow cycle speeds as well as requiring more products to be put on a pallet for shipping.

We were called in to design control panels that would ensure the efficiency and accuracy of weighing and batching their goods into secure bags of various sizes, depending on the recipe selected, while ensuring seamless sealing. The system then needed to control the next step in transferring the filled bags for distribution, requiring an automated Robot system that could stack these bags onto pallets.

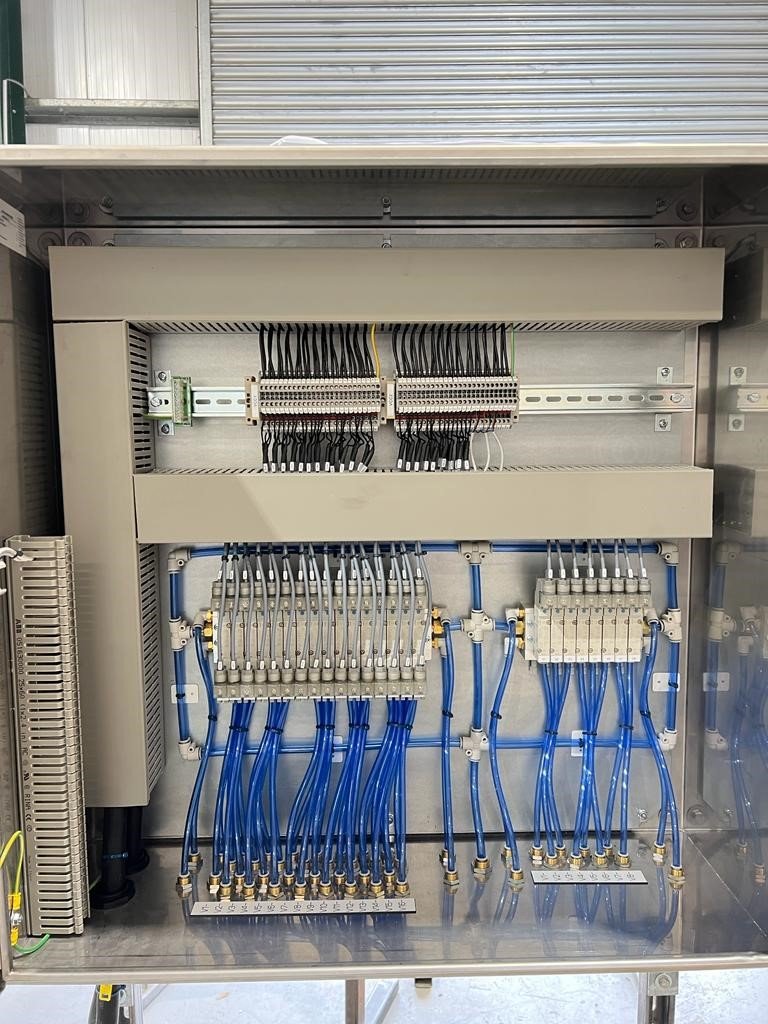

Importantly, the pneumatic solenoid valves found in one of the existing electrical control panels needed to be moved to a separate panel to avoid a possible systems failure due to water in the compressed air source.

Manufacturing

Increased systems performance

Modernise production line

Two new automation and control panels

New pneumatic valve panel

The Solution

Our team of experts defined, built, and implemented design of three control panels to automate the handling of the packaging of powdered goods with precision and efficiency. One for the Batching System, one for the Pneumatics and one for the Conveyors and Robot control.

The first system involved the batch processing of powdered goods into secure bags that had to be batched to tight tolerances, the bag then went through a Stitcher to seal the top of the bag up. We incorporated cutting-edge technology to automate the batching process, ensuring accuracy, reliability and consistency. Once packaged, the bags seamlessly moved through a network of conveyors, optimising the flow of goods to the subsequent stages of the packaging process.

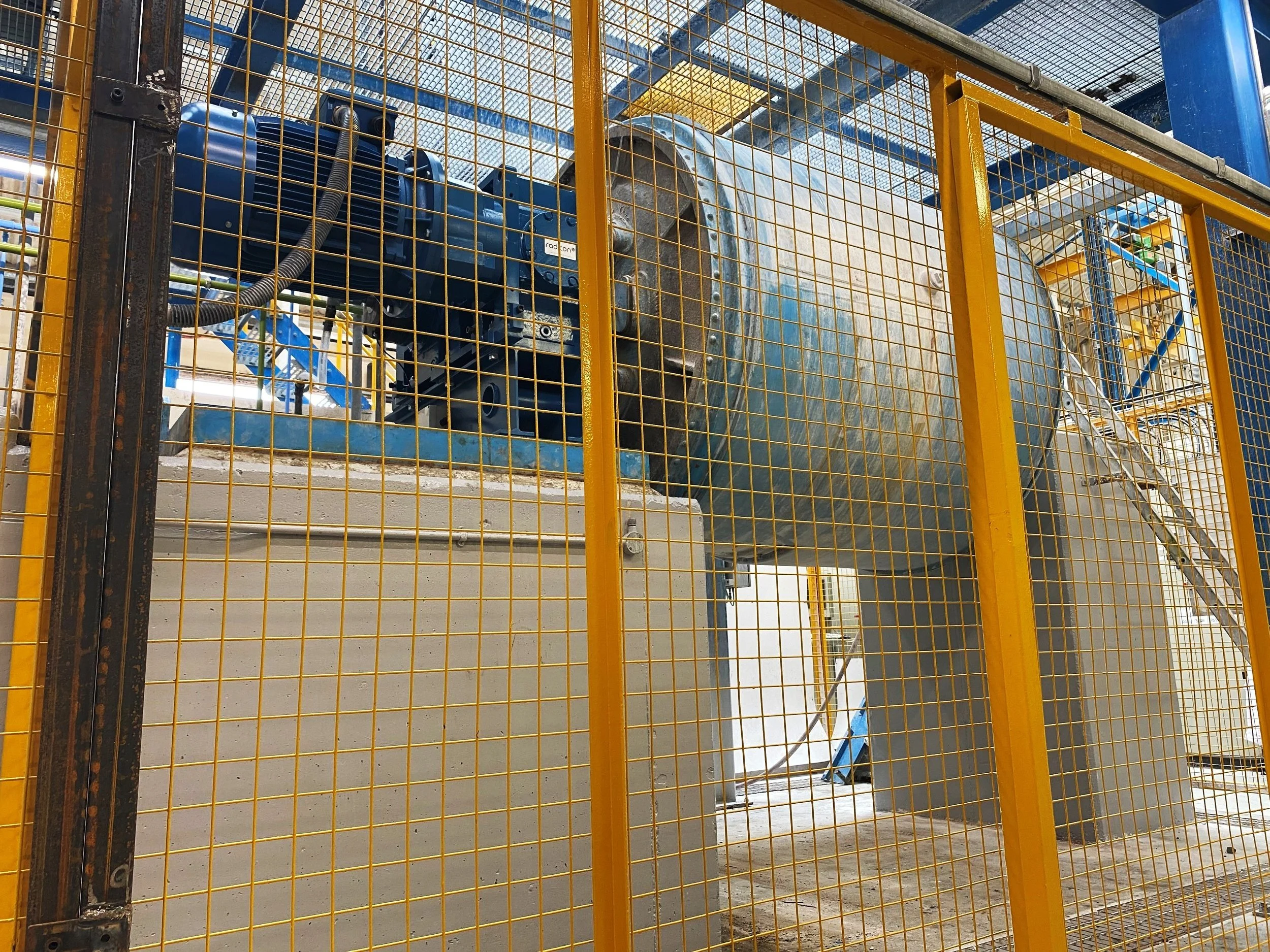

The second system automated a robotic station specifically designed to handle the stacking of bags. This robotic station skilfully received the bags and systematically arranged them onto pallets, stopping at the required height which was determined by a laser height measurement sensor before moving onto the next pallet. The innovative solution not only expedited the packaging process but also ensured the secure and organised arrangement of goods for distribution.

The Implementation

The implementation of these automated systems was a testament to our proficiency in automation and control systems. Our engineers and experts meticulously designed, installed, and commissioned these cutting-edge systems within the food industry's operational setup. Through rigorous testing and fine-tuning, we ensured that the systems seamlessly integrated into the existing infrastructure, minimizing downtime and maximising productivity.

The Results

The successful installation and commissioning of these bespoke automated systems by Total Automated Solutions not only met but exceeded industry standards for best practice packing solutions.

The benefits realised by the included:

Enhanced Efficiency: The automation of the packaging process significantly improved efficiency, streamlining operations and reducing manual labour requirements.

Precision and Consistency: The systems ensured precise batch processing and consistent sealing, maintaining product quality and integrity.

Optimised Distribution: By efficiently stacking bags onto pallets, the systems facilitated easier handling and distribution, reducing logistical complexities.

Safety: Separating the pneumatics system ensured safety compliance requirements and potential systems failure if moisture got in.

The Conclusion

The implementation of these automated systems was a testament to Total Automated Solutions's proficiency in automation and control systems. Our engineers and experts meticulously designed, installed, and commissioned these cutting-edge systems within the food industry's operational setup. Through rigorous testing and fine-tuning, we ensured that the systems seamlessly integrated into the existing infrastructure, minimizing downtime and maximizing productivity, maximising safety.

Our Case Studies