A Modern Makeover

For a traditional Industry

Client

Ceramic Manufacturer

Service Provided

Systems Integration

Location

Midlands

The Challenge

When a Midlands based ceramics manufacturer found it was becoming increasingly less efficient, it reached out to us through the Drive Solutions Centre.

The plant had been running at minimal capacity due to a shortage of operational equipment. A full turnkey solution would be the only option if it wanted to increase system performance and modernise its production line to get the plant back on track.

The plant worked with multiple operating scenarios and had to manufacture on a large scale to tight deadlines. There was simply no room for operational inefficiencies.

Manufacturing

Increased systems performance Modernise production line

Variable Speed Drive installed Built in PLC to control the brake

“We are delighted to be able to refer automation projects to Total Automated Solutions Ltd. Their ability to successfully implement complex automation solutions, generate User Requirement Specifications in conjunction with the client as well as their knowledge of industry standards and practices ensured that each bespoke project is in a safe pair of hands.

From software solutions to MCC build and site work, Total Automated Solutions delivers for both the client and Mitsubishi Electric on time and within budget.

Endorsed by: Diamond Link Training Academy Automation Systems Division”

The Solution

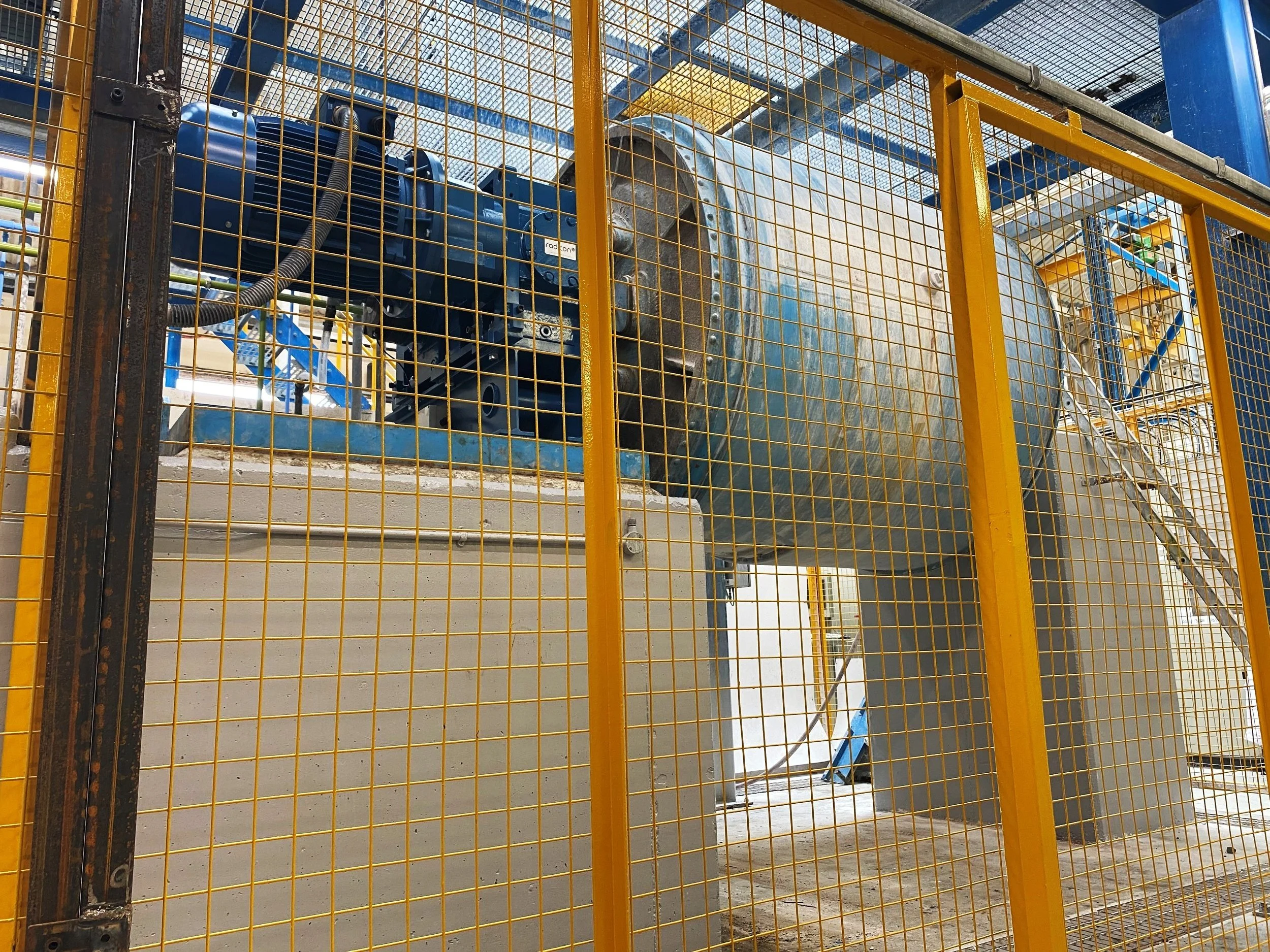

We worked closely with the manufacturer to understand the current control system and overcome the customer’s historical upgrade failures. The solution needed to incorporate a braking system with delayed energisation, for which we played a key role in delivering this full upgrade.

The on site survey determined the system requirements, pre-design and build.

Mitsubishi A840 75kW Variable Speed Drive installed

Utilisation of A840 for built in PLC to control the brake

Full offsite testing of the solution pre-site installation

Speedy site installation and commissioning

With seamless project management between all parties involved, the manufacturer was delighted with the service it received from the Total Automated Solutions team.

The Results

Following the successful implementation of this turnkey solution, the manufacturer reported increased energy efficiencies with the ensuing costs savings, and improved operational flexibility over the previous DOL solution. All of which helped this traditional industry enjoy a much-needed modern makeover.

Our Case Studies