Comprehensive Infrastructure Upgrade of Waste Recycling Facility

Upgraded MCCs for Facility Picking Lines and Optimised Fluid Tank Control Systems

Client

Leading Waste-Recycling Company

Location

Midlands

Service Provided New Control Systems

The Challenge

Following a recent acquisition, our client in the waste management and recycling sector required a comprehensive Motor Control Centre (MCC) replacement at their Midlands facility.

The project scope involved upgrading the MCCs for two picking lines and developing a permanent solution for a problematic process fluid tank. The tank’s original control system—utilizing a basic float switch and Direct-on-Line (DOL) starter—caused frequent overflows and excessive on/off cycling, leading to premature pump wear and high maintenance costs.

Waste Management

Control Centres for picking lines and solution to prevent overflow

Design, Build Install 2 new MCCs and control system for Fluid Tank

“We have worked with Total Automated Solutions for many years, and I highly recommend them. They have helped us through several complex site challenges, working with us to find practical and cost-effective solutions. They are professional and responsive to our needs and have been fundamental in getting us to the positive position we are now in with automated and remotely operated on-site systems.”

The Solution

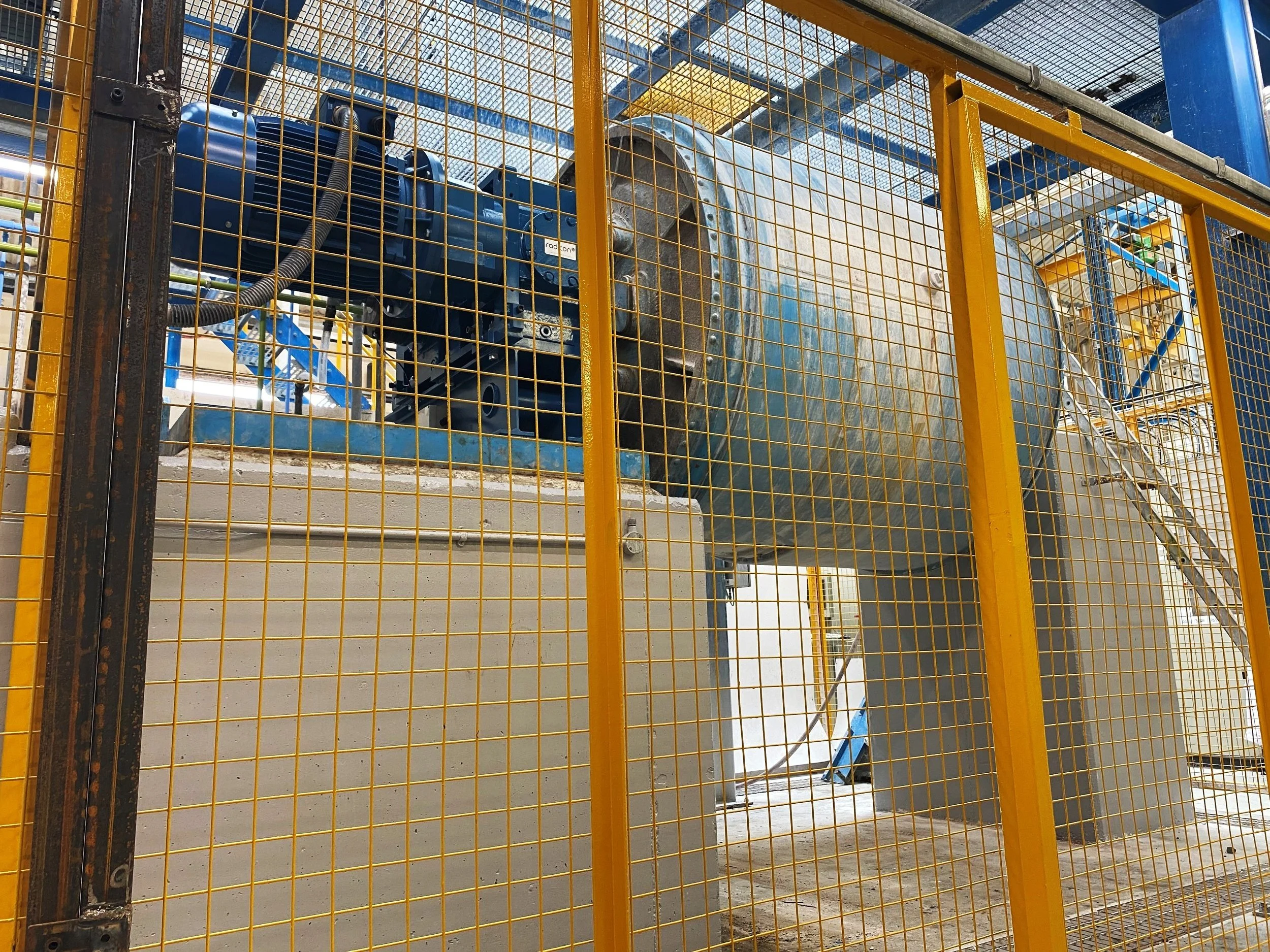

To replace the existing Motor Control Centres (MCCs), Total Automated Solutions designed, manufactured, installed, and commissioned two fully upgraded units using an end-to-end Schneider Electric solution. This high-spec integration featured PLCs, HMIs, soft starters, and ATV930 variable speed drives.

A key challenge involved one MCC being located in a permanently wet area. To ensure long-term protection and reliability, we designed and installed a custom DRG staging platform, elevating the system to guarantee secure operation even in these challenging conditions.

The fluid tank was originally controlled via a Direct-on-Line (DOL) starter and float switch, leading to frequent on/off cycling. This excessive switching caused premature pump wear, high maintenance demands, and frequent tank overflows.

To resolve this, we implemented radar-level measurement and a Schneider Electric ATV 930 VSD. This combination provides smooth, proportional pump control, which has significantly reduced pump wear, improved process stability, and eliminated the risk of overflow.

The Results

By upgrading the system, we delivered a future-proof solution that bolsters MCC and picking line reliability. This overhaul didn't just meet safety requirements—it exceeded them. Key results include a measurable reduction in downtime and the implementation of precise tank level controls, which protects pump health and slashes maintenance overhead. The result is a safe, high-performance installation ready to power the facility’s growth for years to come.

Our Case Studies