Renewable Energy Project

Control System to incorporate a generator that produces hydraulic power

Client

Spaans Babcock

Location

Somerset

Service Provided Systems Integration

The Challenge

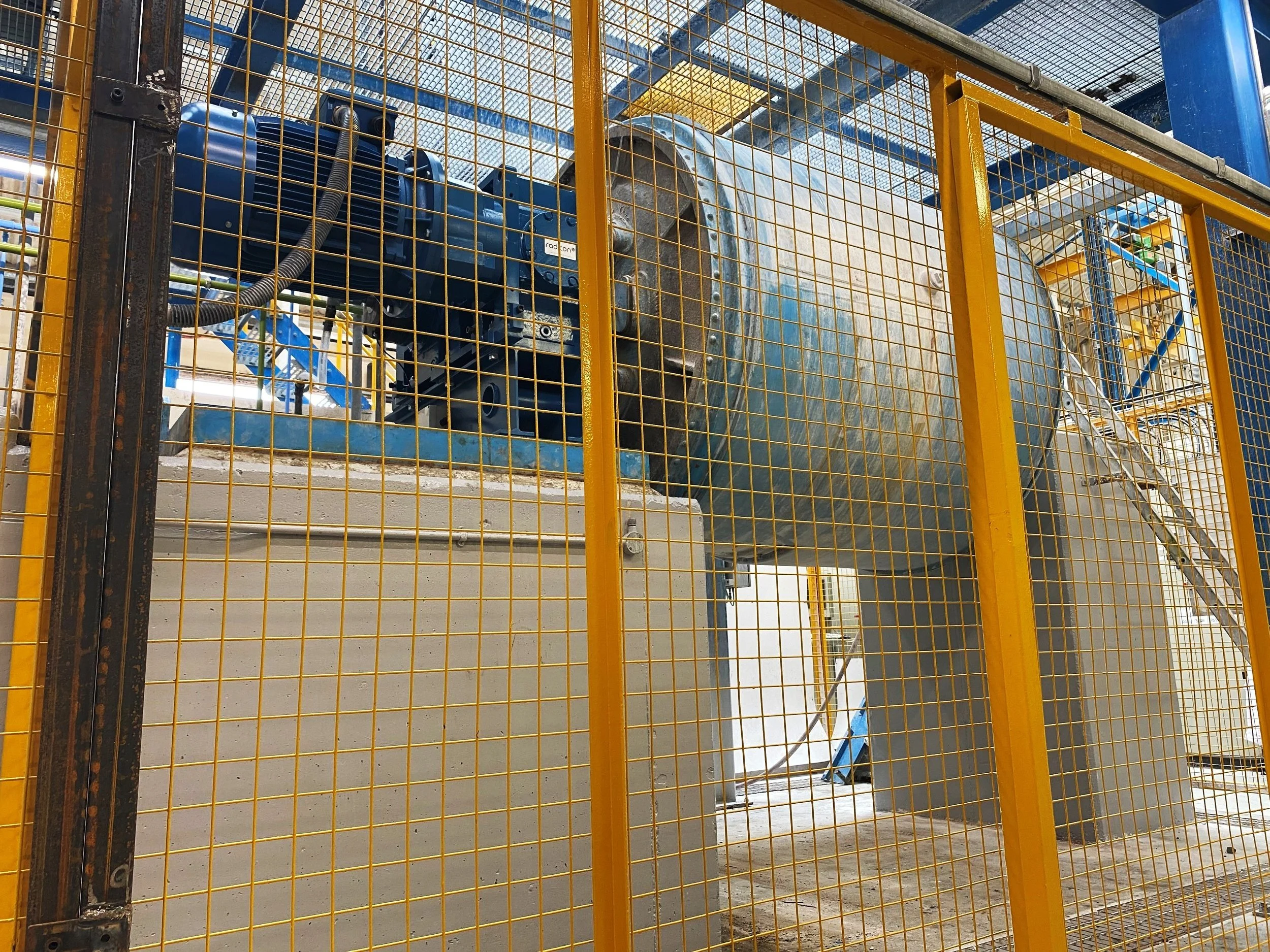

With energy costs continuing to remain high and an ongoing desire for renewable energy solutions, Total Automated Solutions was approached by Spaans Babcock, a leading screw generator manufacturer to help design a control system that could incorporate one of their generators to produce electricity at a river location near Glastonbury.

The innovative control system needed to help support electricity generation taking place courtesy of an unusual renewable source ‐ the power of running river water.

Water generated energy

Designed control system Automation of screw generator

Installation of HMI running with the WinAC MP soft PLC system

“We have used Total Automated Solutions for all of our Toshiba DCS & PLC related projects. Not only are they knowledgeable of the product, but also have the added benefit of providing a full commissioning service and after project support.”

The Solution

The innovative solution was the installation of a Siemens MP277 HMI running with the WinAC MP soft PLC system which helps manage the day‐to‐day operation of a 11Kw Screw Generator and the solution is believed to be the first fully commissioned unit of its type in the UK.

The generator uses the hydraulic power created by a head drop in the river at a weir point to operate an Archimedean screw attached to a motor which when rotated generates electricity. With total cost a real consideration in the overall design of the control system, a number of alternative systems were examined, but in the end the flexibility and benefits offered by the WinAC MP277 proved to be the best overall combination of cost efficiency and solution benefits.

It would deliver an estimated 25‐30% cost saving when compared to other such control systems. The WinAC MP277 provides a number of design benefits that include simple implementation with no added requirement for multiple systems such as data loggers or complicated communications protocol converters.

The benefits also include power monitoring without the added expense of large I/O modules, downloadable historic trending easily accessed via web‐based functionality, and remote connectivity which is extremely helpful given the river location of the generator.

The Results

The resultant generated electricity is used primarily as an energy source to power the home of the occupant. However, under heavy rain fall and the subsequent greater river flow, any power not consumed by domestic use is exported onto the National Grid.

All power generated by this application is monitored by the regional electricity supplier and is bought from the house owner at a per KW rate dependent upon the applicable tariff. Once the screw generator was fully operational on site, Total Automated Solutions still worked closely with the client to refine the system, thus ensuring maximum energy production. The aim was to produce between 1.5kw under low flow conditions, and 13kw under high flow. This underpinned a maintained maximum energy production 24 /7, 365 days a year.

Our Case Studies